Despre noi

Bine ați venit la Lang & Sin – Soluții de Top pentru Prelucrarea Tablei

Peste 20 de Ani de Expertiză și Peste 300 de Clienți Mulțumiți în Industria Prelucrării Metalelor

Înființată în 2002, LANG & SIN SRL s-a impus ca un lider în soluții tehnologice pentru prelucrarea tablelor subțiri în România. Specializați în tehnici avansate de ștanțare și îndoire a metalelor, ne dedicăm să oferim echipamente de înaltă calitate și consultanță expertă în prelucrarea metalului pentru afaceri de toate dimensiunile. Cu o experiență bogată acumulată în peste douăzeci de ani și un portofoliu impresionant de peste 300 de clienți mulțumiți, echipa noastră de specialiști este pregătită să vă asiste în găsirea celor mai eficiente soluții de îndoire și ștanțare, adaptate nevoilor afacerii dumneavoastră.

Produse de Înaltă Calitate de la Producători de Top

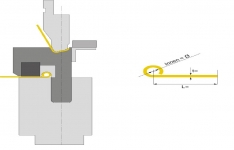

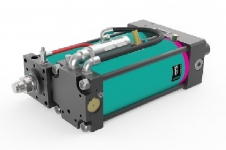

- Scule de Ștanțat: Oferim o gamă variată de scule de ștanțat CNC compatibile cu sisteme Thick Turret și Trumpf, produse de MATE Precision Technologies. Aceste scule sunt ideale pentru mașini de la Amada, Prima Power, Durma, Euromac, asigurând precizie și durabilitate.

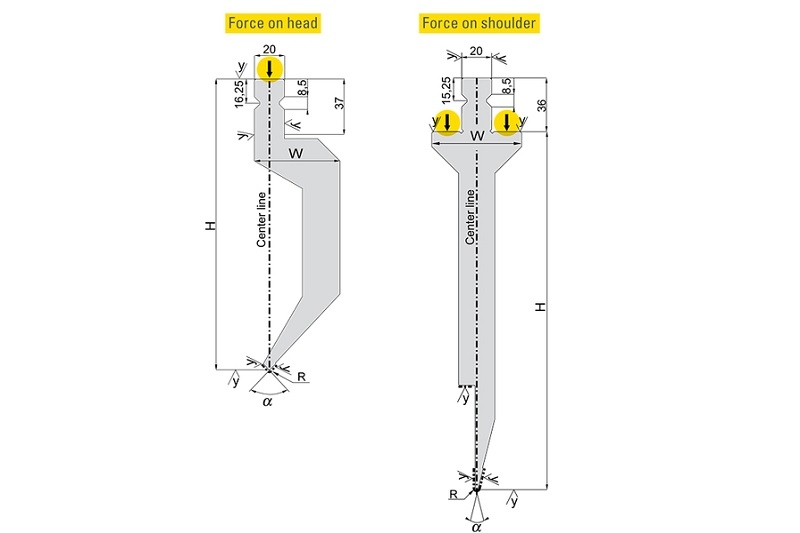

- Scule pentru Prese Abkant și Cuțite pentru Ghilotine: Colaborăm cu UKB, un producător german renumit, pentru a vă furniza scule de înaltă calitate, inclusiv poansoane și matrite pentru abkant, precum și prisme pentru îndoirea tablei. Compatibilitatea extinsă include presele de la Ermaksan, Durma, Wila, Baykal, Bystronic, SafanDarley, Trumpf.

- Elemente Optice și Consumabile pentru Debitarea cu Laser: Complementăm oferta noastră cu produse de la Ophir, RayTools și Centricut, incluzând oglinzi, lentile, duze și elemente ceramice pentru o debitare eficientă și precisă.

Consultanță și Asistență Personalizată

La Lang & Sin, nu vă oferim doar tehnologie de vârf, ci și parteneriat. Fie că aveți aplicații simple sau complexe, suntem partenerul dvs. de încredere pentru optimizarea prelucrării tablelor subțiri. Echipa noastră de experți este gata să vă ofere consultanță gratuită, atât înainte cât și după achiziție, pentru a vă asigura că alegeți soluțiile optimale pentru nevoile dvs. specifice.

De Ce Lang & Sin?

- Experiență Amplă: Cu o istorie de peste două decenii pe piața românească, avem cunoștințele și expertiza necesare pentru a vă ghida în orice provocare tehnică.

- Produse de Calitate Superioară: Colaborăm exclusiv cu producători de renume, asigurându-vă acces la echipamente de top.

- Consultanță și Suport: Oferim asistență personalizată pentru fiecare client, ajutându-vă să faceți alegeri informate.

Contactați-ne Astăzi

Pentru mai multe informații despre produsele și serviciile noastre sau pentru a solicita un apel de consulanță, vă invităm să ne contactați. Descoperiți cum Lang & Sin vă poate ajuta să îmbunătățiți eficiența și productivitatea în prelucrarea tablei.